Introduction to Laser Cleaning Technology

Laser cleaning is a mature surface cleaning technology which embodies the removal of contaminants on surfaces by irradiating with laser pulse. Laser cleaning is also unique, less back and eco-friendly than traditional clean up methods.

How Laser Cleaning Machines Work

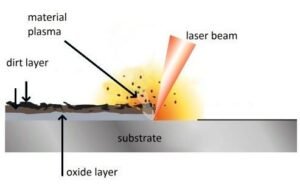

In a laser cleaning system, a concentrated laser beam is projected on the workpiece. The laser energy will heat the contaminants and that in turn will cause the contaminants to either evaporate.

Hey, Check Out This Laser Cleaning Thing!

So, you know how we usually clean stuff in industry? Seriously, laser cleaning is wild. It’s the modern-day solution to getting surfaces spotless, and honestly, the way we clean things is never going to be the same

Where Are People Using This? 🤔

It’s popping up everywhere! You see it used by all the major players. Think auto manufacturing—they use it to clean up engine parts, strip paint, and get rid of rust before the next step. And for aerospace, where everything has to be absolutely perfect, the precision is exactly what they need.

https://www.youtube.com/watch?v=F8MxlXYnXOQ&t=10s

Airplanes (Aerospace): This is where they need extreme precision. They use it to meticulously clean complex pieces, like those expensive turbine blades.

Electronics: It can even clean super delicate circuit boards, zapping away residues without frying the components.

What’s So Great About It? The Perks! 👍

Seriously, the benefits are massive, especially when you compare this to the messy methods we used before. For starters, it’s super green! You don’t have to deal with any disgusting chemicals or solvents at all.

This thing has pinpoint accuracy. I mean, it can clean the tiniest spots and those areas you usually can’t even get to. If you have a delicate surface, it’s perfect because you’re only hitting the exact spot that needs cleaning.

Super Fast: This thing is quick! That means they don’t have to shut down the factory for ages. Seriously, less downtime equals way more cash in the bank.

Another huge plus is zero damage. Since you’re not using anything abrasive—no scraping or scrubbing—you don’t wear away the original material at all.

The Different Kinds of Laser Tools 🔦

They have a few different setups depending on the job:

Basically, you’ve got three main types. Fiber Lasers are the main event—they’re the big guns for serious factory work. Then you have Diode Lasers for quick, less demanding jobs. And finally, if the mess is really thick or tough, you reach for the CO2 Laser.

Why It Beats the Old Methods (Like Sandblasting) 🥊

Remember sandblasting or strong chemicals? They’re messy, create hazardous waste, and just generally suck.

Laser cleaning is a dry process, it’s super precise, and it creates virtually no waste you have to worry about. It’s just safer and way more efficient.

Some of the Coolest Jobs It Does:

Rust? Gone! It removes rust flawlessly without scratching or warping the metal underneath. Forget the acid baths!

Saving History: This is cool—they use it in art restoration to clean historical sculptures and buildings made of stone or wood. It cleans the dirt without harming the original ancient material.

So, speaking of the different lasers (Fiber, Diode, CO2), are you curious about which one is actually the most popular choice for general manufacturing?

Wear the Right Glasses! This is the most critical thing. You can’t just wear your normal safety goggles. You need special laser protective eyewear. These lasers can cause serious, permanent eye damage, so keep those things on the entire time—no peeking!

Ventilation is Key: When the laser zaps off rust or paint, it basically vaporizes it. That creates fumes and tiny particles, and you do not want to breathe those in. So, make sure the work area is really well-ventilated or that you have a strong fume extractor sucking up all that residue.

Final Word on Safety: Listen Up, This Is Crucial!

“Alright, look, this cleaning method is incredible, but we are dealing with high-power lasers, so we need to be completely on point with safety. Here are the three things you absolutely must lock into your brain:”

- Protect Your Eyes – No Exceptions! 👓

“Seriously, your eyes are priority number one. You cannot just wear regular safety glasses! You need the special, rated laser protective goggles. These beams can cause permanent eye damage, fast. Those goggles have to stay on your face the entire time the machine is running—I mean zero peeking! If those come off, you stop working.”

- Manage the Air – Ventilation is a Must! 💨

So, always check that the area is super well-ventilated, or make darn sure that fume extractor is running strong and sucking up all that crap.”